Core Technical Advantages

Silicon carbide (SiC) power modules, integrating SiC MOSFETs and diodes into compact, thermally optimized packages, deliver transformative performance compared to traditional silicon (Si) IGBT modules. Their wide bandgap (3.26 eV) enables operation at higher voltages (up to 10 kV) and temperatures (up to 200°C), far exceeding Si’s limits (1.2 kV, 150°C). This allows SiC modules to achieve a 50% reduction in conduction losses—on-resistance (Rₒₙ) for a 1200 V SiC MOSFET is 8 mΩ·cm², half that of a Si IGBT (16 mΩ·cm²)—while switching losses are cut by 70% due to faster switching speeds (100 kHz vs. 20 kHz for Si).

Thermal efficiency is a standout feature. SiC’s high thermal conductivity (490 W/m·K) is 3x that of Si (150 W/m·K), enabling more effective heat dissipation. A 100 kW SiC module from Infineon operates at a junction-to-case thermal resistance (Rth(j-c)) of 0.2°C/W, 40% lower than a comparable Si module (0.33°C/W), reducing the need for bulky cooling systems. This translates to a 20% reduction in overall system weight for electric vehicle (EV) traction inverters.

Power density gains are substantial. SiC modules achieve 50 W/cm³, double the density of Si modules (25 W/cm³), due to smaller passive components enabled by higher switching frequencies. A 500 kW SiC-based inverter for wind turbines occupies 0.5 m³, half the volume of a Si equivalent, while maintaining 99.2% efficiency—0.5% higher than Si, which equates to 5,000 kWh/year energy savings for a 1 MW turbine.

Key Breakthroughs

Recent advancements in packaging technology have enhanced reliability. Silver sintering die-attach replaces traditional solder, increasing thermal conductivity from 50 W/m·K to 200 W/m·K and improving temperature cycling endurance (1,500 cycles vs. 1,000 cycles for solder). STMicroelectronics’ 1200 V SiC module with sintered attachments achieves a mean time between failures (MTBF) of 10 million hours, 2x higher than earlier designs, meeting automotive grade requirements.

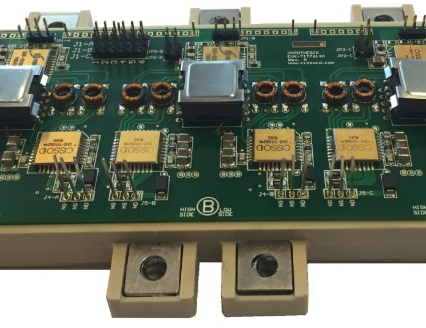

Module integration has progressed significantly. 3D stacked SiC modules with integrated gate drivers reduce parasitic inductance to 5 nH, down from 20 nH in discrete designs, enabling switching speeds of 200 kHz without voltage overshoot. Texas Instruments’ isolated gate driver for SiC modules cuts dead time to 50 ns, 75% shorter than Si-compatible drivers, further reducing switching losses by 15%.

Cost reduction efforts have yielded results. 6-inch SiC wafer production now achieves a defect density below 0.5 cm⁻², up from 5 cm⁻² in 2018, increasing die yield from 50% to 80%. This has reduced the cost of a 1200 V/200 A SiC module to 1,000 in 2019, narrowing the gap with Si modules ($300) while maintaining performance advantages.

Industry Applications

In electric vehicles, SiC modules are driving range improvements. Tesla’s 4680-based EV platform uses 1200 V SiC traction inverters, achieving 97% efficiency—3% higher than Si IGBTs—extending range by 10% (approximately 50 km for a 500 km range vehicle). The higher switching frequency also eliminates 2 kg of copper from the motor, reducing overall vehicle weight.

Renewable energy systems benefit from SiC’s efficiency. A 3 MW solar inverter using SiC modules from Huawei achieves 99.5% efficiency, up from 99% with Si, adding 15,000 kWh/year to a 100 MW solar farm’s output. For energy storage systems (ESS), SiC-based bidirectional converters cut charging losses by 25%, reducing battery degradation and extending cycle life by 10%.

Industrial motor drives leverage SiC’s power density. A 200 kW SiC module in ABB’s variable frequency drive (VFD) reduces cabinet size by 40% compared to Si-based VFDs, while operating at 99% efficiency. This lowers installation costs by $2,000 per drive in factory automation systems, with payback periods under 2 years.

Challenges

Despite progress, cost remains a barrier for mass adoption. SiC modules still cost 60% more than Si IGBT modules at equivalent power ratings, primarily due to wafer and processing expenses. While 6-inch wafers have reduced costs, they are still 5x more expensive than 8-inch Si wafers, and the complex epitaxy process adds 30% to manufacturing costs.

Reliability under extreme conditions needs improvement. SiC MOSFETs exhibit threshold voltage drift under high-temperature, high-voltage stress, with shifts exceeding 1 V after 1,000 hours at 175°C—double the acceptable limit for automotive applications. Gate driver optimization has reduced this to 0.5 V, but further material engineering (e.g., AlGaN buffer layers) is required.

Supply chain constraints persist. Global SiC wafer capacity is approximately 1.5 million 6-inch equivalent wafers/year, while demand for EV and renewable applications exceeds 2 million, leading to 6-12 month lead times. Expansions by Wolfspeed and II-VI are targeting 3 million wafers/year by 2025, but ramp-up challenges may delay capacity relief.

Silicon carbide power modules are critical to decarbonization efforts, with BloombergNEF projecting a $15 billion market by 2030, driven by EVs, renewables, and industrial applications. As costs continue to fall—targeting parity with Si by 2027—and reliability improves, SiC will replace Si in most high-power applications, enabling a new generation of energy-efficient systems. The next five years will see further innovations in packaging, wafer scaling, and supply chain resilience, solidifying SiC’s role as the material of choice for high-performance power electronics.

-

Wechat

-

Whatsapp