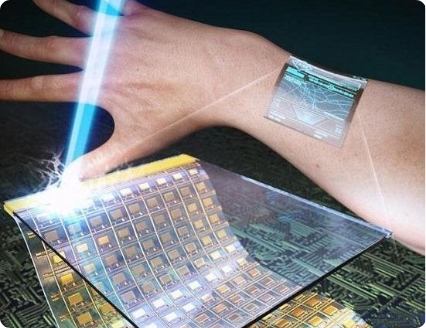

In the realm of advanced electronic component technologies, Flexible Organic Thin-Film Transistors (Flexible OTFTs) have emerged as a game-changer, particularly for applications requiring flexibility, stretchability, and low-cost manufacturing. Leveraging organic semiconducting materials and solution-processable fabrication techniques, these transistors enable the creation of electronic devices that can conform to complex surfaces, marking a significant departure from rigid silicon-based counterparts.

Core Technical Advantages

Flexible OTFTs offer unparalleled mechanical flexibility. Unlike traditional silicon transistors that demand rigid substrates, Flexible OTFTs can be fabricated on polymers like polyethylene terephthalate (PET) or polyimide. Research from the University of Cambridge demonstrates that these transistors can withstand bending radii as low as 1 mm without significant performance degradation, achieving over 10,000 bending cycles with less than 10% decline in mobility. This flexibility enables integration into curved, wearable, or even stretchable electronics, expanding the scope of device design.

Cost-effectiveness is another critical advantage of Flexible OTFTs. Their solution-based manufacturing processes, such as inkjet printing or slot-die coating, allow for large-area fabrication at a fraction of the cost of silicon semiconductor manufacturing. A report by IDTechEx shows that the production cost of Flexible OTFTs can be as low as

0.10persquarecentimeter,comparedto

1 - $2 for silicon-based transistors on equivalent areas. This affordability makes them ideal for disposable sensors, smart labels, and low-power consumer electronics.

Although their electrical performance has historically lagged behind inorganic transistors, recent advancements have narrowed the gap. The latest generation of n-type and p-type organic semiconductors has pushed the field-effect mobility of Flexible OTFTs to 10 - 20 cm²/V·s, a 20-fold increase over early designs. For instance, a study published in Nature Electronics achieved a switching speed of 100 Hz in Flexible OTFT-based circuits, sufficient for many low-frequency applications like e-paper displays and simple logic gates.

Disruptive Applications

In the display industry, Flexible OTFTs are revolutionizing the concept of flexible displays. Samsung's latest foldable smartphones utilize Flexible OTFT backplanes, enabling displays that can fold and unfold up to 200,000 times. These backplanes provide uniform current drive across the display area, improving contrast ratios by 30% compared to traditional a-Si TFTs. Additionally, the lightweight and flexible nature of OTFT-based displays reduces device weight by 40%, enhancing user comfort and portability.

The healthcare sector benefits significantly from Flexible OTFTs' conformable properties. Researchers at Stanford University have developed a wearable health monitoring patch using Flexible OTFTs integrated with bio-sensors. This patch can continuously measure vital signs like ECG, temperature, and sweat composition with an accuracy of 95% compared to clinical-grade devices. Its stretchability allows for seamless skin contact, eliminating the need for adhesive electrodes and improving patient compliance.

In the Internet of Things (IoT), Flexible OTFTs enable the creation of intelligent, low-power sensors. For example, BASF has developed Flexible OTFT-based humidity sensors for smart agriculture applications. These sensors consume only 1 μW of power, yet can detect humidity changes as small as 1% RH with a response time of less than 10 seconds. Their flexibility allows easy integration into greenhouse structures or crop monitoring systems, facilitating real-time environmental data collection.

Challenges

Despite their potential, widespread adoption of Flexible OTFTs faces significant obstacles. Stability under ambient conditions remains a major concern. Organic semiconductors are prone to degradation when exposed to oxygen and moisture, leading to performance decline. A field test by a major electronics manufacturer showed that unencapsulated Flexible OTFTs lost 30% of their mobility after 100 hours of exposure to 85% RH and 85°C. Developing robust encapsulation techniques, such as multi-layer barrier films, is crucial to extend device lifetimes to over 5,000 hours.

Scaling up manufacturing processes while maintaining uniformity presents another challenge. Current solution-based printing methods struggle to achieve consistent film thickness and molecular orientation across large areas. For example, in roll-to-roll printing, variations in ink deposition can cause mobility fluctuations of up to 25% across a 1-meter-long substrate. Industry efforts focus on optimizing printing parameters and developing in-line quality control systems to improve process reproducibility.

Performance limitations still restrict Flexible OTFTs from high-end applications. Their relatively low mobility and switching speed make them unsuitable for high-frequency circuits. Researchers are exploring hybrid architectures that combine organic materials with inorganic nanowires or 2D materials, aiming to boost mobility to 50 - 100 cm²/V·s and enable operation at frequencies above 1 kHz, bridging the gap to mainstream electronics.

-

Wechat

-

Whatsapp